HEA consisting predominantly of refractory elements with high melting point such as Nb, V, Zr, Ta, Hf, Mo, and W, is generally considered as refractory high entropy alloy (RHEA). This makes HEAs possess outstanding properties such as high hardness and strength, excellent thermal stability, high toughness, good ductility, excellent oxidation, wear and corrosion resistance, and so on, providing a new choice for development of high-performance materials. Consequently, HEAs have unique effects including high entropy, lattice distorsion, sluggish diffusion, and cocktail compared with traditional alloys. Different from traditional alloys with one or two dominating basic elements, such as nickel-based superalloy, titanium alloy, and so on, HEAs referred as multi-principal-element alloys, concentrated solid solution alloys, baseless alloys, or compositionally complex alloys, are composed of 5 or more elements in equiatomic, near equiatomic or unequi-atomic ratios, in which atomic percentage of each element varies from 5% to 35%.

High entropy alloy (HEA) is a subversive new concept of alloy design proposed by Yeh et al. Therefore, it is necessary to develop revolutionary new high-temperature structural materials. High temperature ceramic, intermetallic, and Co-Re-based alloy studied for substitutes for nickel-based superalloys, are incapable of the requirement of turbine disk-blade/vane performance. This is also true to those cast superalloys for turbine blades or vanes. For example, at present, nickel-based superalloy is prevailingly used, but it is approaching the limits for improving operating temperature of turbine disk due to approaching design limits of alloy composition and serious difficulty to the manufacture of highly alloyed forgings. The requirement for higher temperature materials with superior performance is more stringent due to more and more complex and harsh service environment with the rapid development in the fields of aerospace, aircraft, nuclear reactors, transportation, chemistry, and other fields. This review will give a deep understanding of the effects of different factors on the service performance and provide scientific guide in designing RHEAs with improved performance.

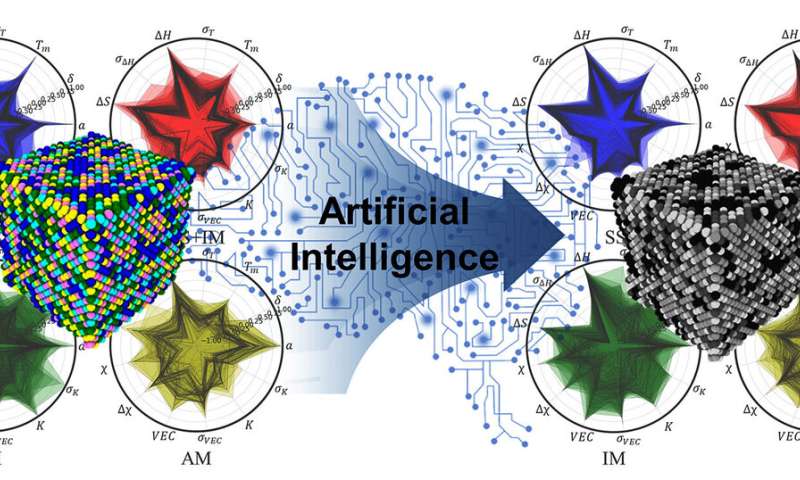

Finally, some important research areas to be carried out in future are pointed out. Based on this, the influence of heat treatment on microstructures prior to and after the deformation is further summarized. Then, hot deformation behavior and plastic deformation under different loadings are analyzed. This is followed by different preparation methods and the comparison of strengths and shortcomings based on different RHEAs. Firstly, the alloy systems and strengthening mechanism are introduced. It mainly covers alloying system and strengthening mechanism, the preparation method, plastic deformation and the related mechanism, as well as microstructure control by heat treatment. Herein, contemporary aspects of corresponding development of RHEAs are reviewed to discuss various factors affecting the organization structure and service performance. Owing to superior comprehensive performance than conventional superalloys at high temperature, refractory high entropy alloy (RHEA) is becoming a promising candidate for the next generation high-temperature material.

0 kommentar(er)

0 kommentar(er)